Zhengyuan's business: Grinding Equipment Manufacturing

Grinding mills are primarily used for breaking solid materials into various-sized powders. As a result, grinding machines are ideal equipment for a wide variety of applications, including changing for grain shape, grain size and particle size distribution, etc.

Our air classifiers, which include self-diffluent classifiers and multi-stage classifiers, are mainly used to sort materials by the combination of particle size, density and shape, etc.; and also used to wipe off impurities in powder materials. Specifically, air separators can be used for separating coarse materials in submicron powders and nano-powders.

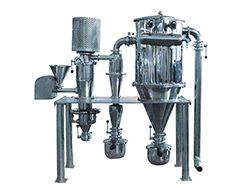

Our Jet mills, which include cyclonic jet mill and fluidized bed jet mills, are extensively used for ultra-fine grinding of various particles, particle separating and particle shaping in the following industries: chemical engineering, mining, fire-resistance manufacturing, food and beverage production as well as metallurgic and porcelain manufacturing, etc.

Our team will work with you to find the right solution for your production needs.

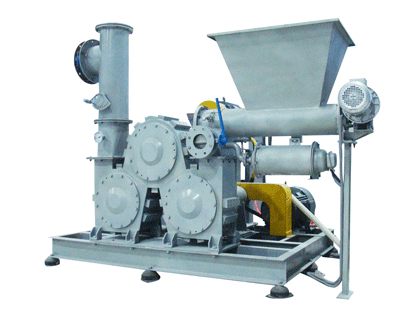

Powder surface modification coating machines generatw heat through high-speed interaction between the rotor and materials, effectively modifying the surface of powder particles. It operates under negative pressure, enabling continuous production with high throughput, low energy consumption, and minimal use of coating agents.

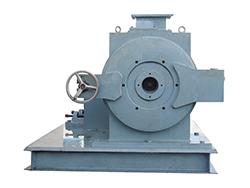

LHZ Vertical Shaping Machine is the preferred shaping equipment for the battery anode material industry. Its capacity is large and the yield rate is high, the finished product has good shaping appearance and high tap density.

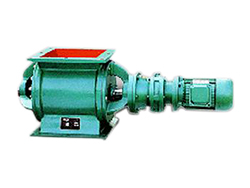

LHV Powder Grinding and classification Machine is independently developed by our company. The finished product produced by this equipment has high particle size reduction rate, the original appearance of the particles will not be destroyed, and the large particles can be strictly filtered. This equipment has been widely used in the preparation of high-end powders in the new materials.

Along with the development of technology, new materials have been widely used. These materials feature the structure that micron-sized materials are covered with nano scale materials. Combining the latest foreign technology, our company develops this conical mixer to help manufacture those new materials.

Low energy consumption: our LHM superfine ball mill production line adopted high advanced energy-saving technology and classification technique; as a result, our production line can save over 40% energy for producing same quantity materials.

LHE wet ultrafine grinding machine is the newly-developed grinding equipment of our company. Designed with totally-new machine structure, optimized machinery size, uniquely- designed machinery parts, and simplified production process, this wet ultrafine grinding machine has higher performance.

This drum blender has a special structure design in which the bearing won't contact with feeding materials directly. Thus, the lubricating of bearings won't cause to feeding materials.

With CMP design style, this mixing equipment features high quality surface treatment and no dead angle in the chamber. Thus, the mixing material can be completely discharged.

Our team will work with you to find the right solution for your production needs.