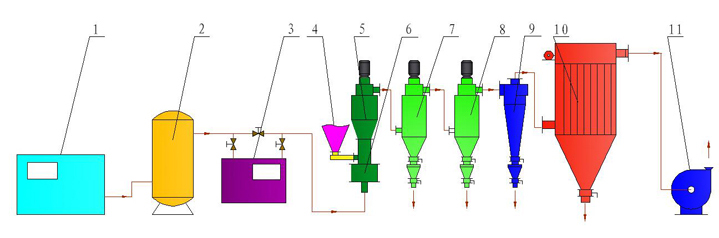

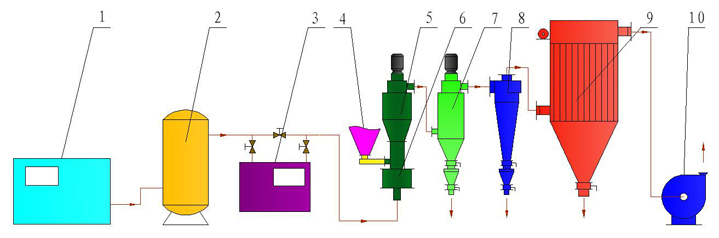

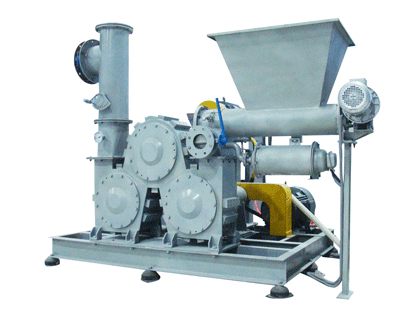

Cyclonic Jet Mill and Classifier

Jet milling and classification are important in producing materials with a controlled particle size distribution. This milling and classifying system offers an ideal solution for creating powders with a narrow size range, making it a preferred choice in industries such as abrasives, battery materials, superhard materials, photoluminescent and reflective substances, pharmaceuticals, pigments, metal oxides, and new chemical materials. Its precision and efficiency have established it as a leading technology in these fields, ensuring reliable performance and consistent quality.