Parameters

| Item \ Model | LHK-40 | LHK-60 | LHK-90 |

| Max. material size | Sawdust | 5-15 mesh |

| Granules | ≤20mm |

| Finished product size | Sawdust | 100-600 mesh |

| Granules | 100-1250 mesh |

| Max. Production capacity | Sawdust | 200kg/h | 300kg/h | 400kg/h |

| Granules | 700 kg/h | 1000kg/h | 1500kg/h |

| Main motor power | 22kw | 30kw | 45kw |

Features

- Energy saving: our wood flour mills can save as much as 30%-40% energy comparing with traditional grinding mills.

- Superfine grinding: finished product fineness could be 600mesh because our wood flour grinding mills are equipped with high precision classifiers.

- Material fineness is adjustable.

- Long service life: wear resistance materials are adopted for making wearing parts.

- User-friendly design enables a convenient clean and maintenance.

- Negative pressure production guaranteed a better production environment.

Working Principle

After materials are fed into milling chamber, they will be pulverized under the shear force and extrusion force generated between grinding roller and grinding ring. And classifiers on the top of these impact mills will collect qualified powders.

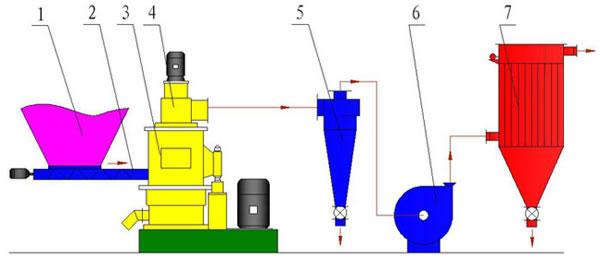

Process Flow

1. Storage hopper

2. Screw conveyor for material feeding

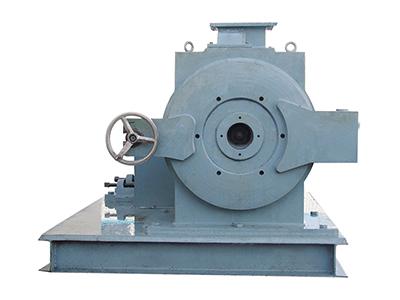

3. Main machine of wood flour mill

4. Classifier

5. Cyclonic collector

6. Induced draft fan

7. Pulsed dust collector

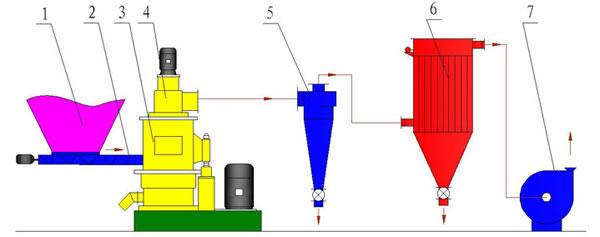

1. Storage hopper

2. Screw conveyor for material feeding

3. Main machine of wood flour grinding mill

4. Classifier

5. Cyclonic collector

6. Pulsed dust collector

7. Induced draft fan