Parameters

| Spec \ Data | LHB-E | LHB-F | LHB-G | LHB-K | LHB-N | LHB-M | LHB-Q | LHB-S | LHB-D | LHB-T |

| Handling capacity (t/h) | 0.05~0.25 | 0.3~1.0 | 0.6~2.0 | 1.5~3.0 | 3~ 6.0 | 6.0~12 | 13~26 | 30~50 | 50~80 | 80~120 |

| Fineness (um) | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 |

| Efficiency (η=%) | 70~90 | 70~90 | 70~90 | 70~90 | 70~90 | 70~90 | 70~90 | 70~90 | 70~90 | 70~90 |

| Main power (kw) | 1.5-2.2 | 3-4 | 5.5-7.5 | 7.5-11 | 15-22 | 22-37 | 30-55 | 75-90 | 90-110 | 132-160 |

Features

- Reduces energy consumption by 50% compared to other classifiers while boosting classification efficiency by 50%

- Ensures fine particle classification, completely eliminating oversized particles or unwanted residues in the final product

- Operates at 50% lower rotation speed than other horizontal and vertical classifiers, while maintaining the same classification precision

- Can be equipped with specialized classification structures to meet specific processing requirements

- Compatible with various grinding systems, including ball mills, Raymond mills, impact mills, and jet mills, forming either closed or open-circuit systems

- Operates under negative pressure, preventing dust pollution and maintaining a clean working environment

- Offers a high level of automation, stability, and ease of operation

Applications

- Ideal for ultrafine powder classification, impurity removal, and particle dispersion

- Suitable for classifying coarse particles mixed with ultrafine and nano powders, as well as materials that are sticky, highly agglomerated, difficult to disperse, or have poor flow properties

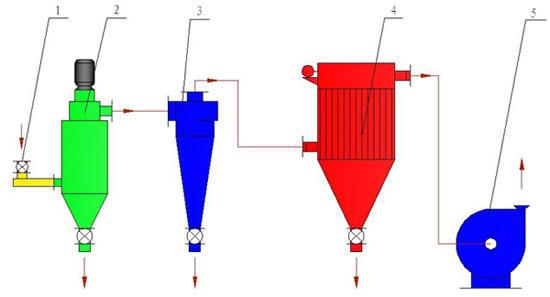

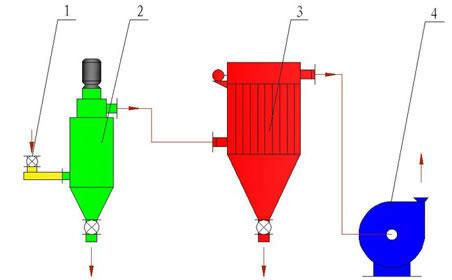

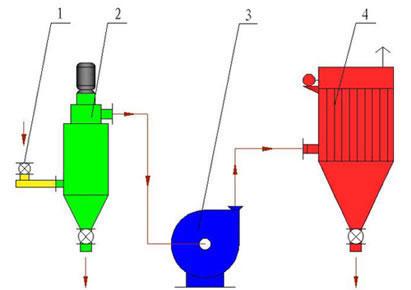

Process Flow

1. Feeding system

2. Main machine of self-diffluent classifier

3. Cyclonic collector

4. Pulsed dust collector

5. Induced draft fan

1. Feeding system

2. Classifier

3. Pulsed dust collector

4. Induced draft fan

1. Feeding system

2. Main machine of self-diffluent classifier

3. Induced draft fan

4. Pulsed dust collector

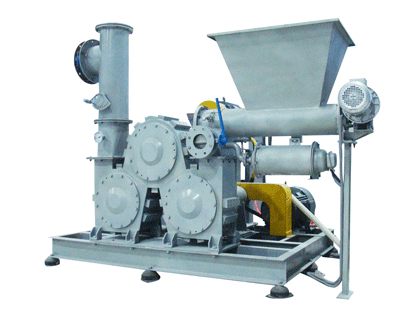

Operation Principles

Materials run into the first self-diffluent classifier section after feeding, and most coarse particles have been separated; Powder with few coarse particles will be brought up to the turbine classifier section by upward cyclone for second separation. Superfine powder will then be collected and the coarse particles will be discharged through the outlet valve.