Features

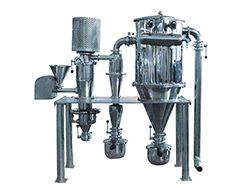

LHJ-10 laboratorial superfine impact mill is a kind of lab mini mill designed by our company. It is especially suitable for applications of Universities and Enterprise laboratories. Our lab superfine impact mills have the following features:

- All-in-one design for grinding and classifying. Product particle size ranges from 3 to 100um which is also adjustable. Additionally, it has disaggregation and shaping functions for materials.

- The grinding parts of our impact mills are made of wear-resistance composite materials. As a result, our machines have a long service life.

- This laboratory grinding equipment is especially suitable for food and pharmaceutical industries with GMP standard.

- PLC automatic control system is available, which guaranteed our grinding mills’ reliable running and simple operation.

- Environmentally friendly: (1) no dust pollution for negative pressure production environment. (2) no noise pollution.

Working Principle

Materials are firstly fed into milling chamber. When the chamber is rotating at a high speed, the high impact force generated for the collision between materials and rotary parts helps realize superfine grinding. And then coarse and fine powders are classified in impeller classification system. Qualified powders will be collected by cyclonic collectors and unqualified powders will be ground for the second time. And finally filtered air will be discharged by induced draft fans.

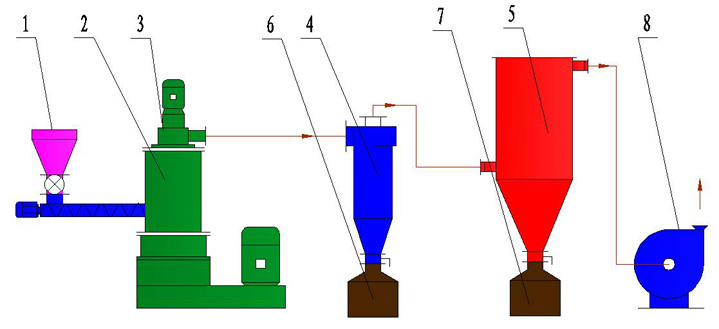

Process Flow

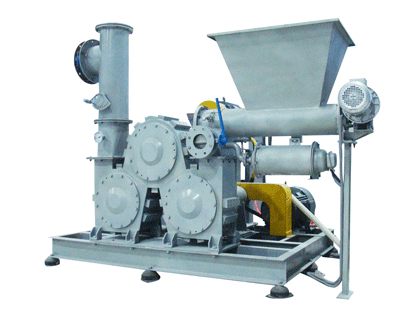

1. Material feeding system

2. Grinding system

3. Classifying system

4. Cyclone separator

5. Bag filter

6. Material collection tank

7. Material collection tank

8. Draft fan