-

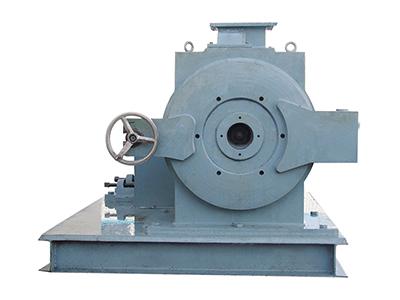

- LHJ Superfine Impact Mill

Low energy consumption: Our superfine impact mills integrated the functions of centrifugal mill, impact grinding mill, etc. together, thus enable a higher crushing capability and lower energy consumption;

High fineness: LHJ series impact mills are equipped with self-diffluent classification system; product fineness: ≥2500 mesh.

-

- LHW Vortex Mill Our vortex mills can be used for normal temperature pulverizing of thermosensitive materials, like rice, cassava fiber, tobacco stems, soy protein, silica gel, magnesium metal, etc. This powder grinding mill is also extensively used in industries like chemical engineering, plastic product manufacturing, non-metallic mines, non ferrous metal product manufacturing, etc.

-

- LHG Roller Mill

Lower energy consumption for producing the same amount of materials.

High fineness: our roller mills are equipped with high precision classification system, which help guarantee high product fineness.

-

- LHQ Classifying Micronizer Firstly, the LHQ classifying micronizer delivers the materials from feeding device to the crushing chamber. The material is smashed through severe friction, shearing and extrusion of high-speed rotor. Then, through the classifier, these materials will be divided into fines and coarse material. Finally, the fines directly enter into the collection system as finished products. And the coarse material will be smashed again after being recovered through the distributing recovery device.

-

- LHD Plastic Pulverizer LHD series plastic pulverizer is mainly used for grinding thermosensitive materials (Mohs hardness: 3), including PVC, PE, PET, PC, LDPE, HDPE, EVA, etc., which feature with high elasticity and impact-resistance. Just because this plastic pulverizer is widely used for pulverizing PVC and PE, it also called as PVC pulverizer or PE pulverizer.

-

- LHI Horizontal Impact Mill Firstly, the LHI horizontal impact mill feeds the materials from feeding device to the crushing chamber. Then, the materials will be smashed through the impact of high-speed rotating hammer. Thus, through the classifier wheel, these materials will have fines and coarse material separation. Finally, the coarse material will be fed into the crushing chamber to be smashed again. And the fines are collected by the collection system.

-

- LHO Hammer Mill Feeding and Grinding: Through the top-installed feeding hole, materials are fed into the milling chamber with speed-adjustable rotors, on which detachable hammers of high hardness are mounted. After the feeding process, materials can be ground into powders by the impact force, shear force, and friction force generated between the hammers and materials.

-

- SH Industrial Shredder Equipped with powerful two-speed swing type hydraulic pusher, which avoids the occurrence of jamming and reduces the wear of the inner rail. The single-shaft shredder is driven by a low-speed and high-torque reducer. This shredder has a smaller footprint than the conventional shredder with horizontal pusher.

-

- LHK Wood Flour Mill Our wood flour mills are primarily used for superfine grinding of fiber texture material and sawdust, etc. As a kind of impact mill, it can also be used for pulverizing of non-metallic materials, feeds, agricultural products, and chemical products, etc. (Note: the Mohs hardness of those materials should be lower than 6).

-

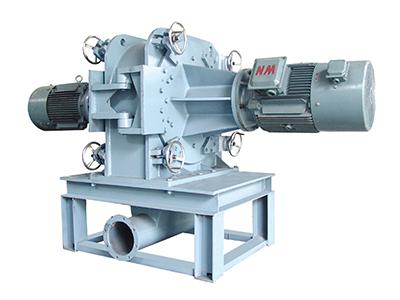

- LHN Pin Mill LHN pin mill delivers the materials from top feeding device to the crushing chamber of main engine. There are two clutch plates mounted with evenly distributed pin bar in the crushing chamber. And also the two clutch plates run at high speed in opposite direction and the highest relative velocity is 250m/s. Then, the materials impact the pin bar at extremely high speed.

-

- LHX Air Swept Mill Product fineness and production capacity can be controlled by vertically adjusting gap size between rotor and stator without dismantling the air swept mill. The adjustment range of gap size is 0-5mm. Some wearing parts such as the rotor are made of composite wear-resistant materials. Thus they feature minimum wear, non-pollution to materials and long service life.

Our team will work with you to find the right solution for your production needs.

- E-mail: wfzy1998@gmail.com

- WhatsApp: +86-13465660184

ShanShan, a company in Inner Mongolia, after carefully evaluating various options, chose our shaping machines for their battery materials production. With over 20 machines running smoothly for more than three years ...

In Uzbekistan, a local company sought to capitalize on its abundant calcite resources to develop a high-grade calcium carbonate project. However, the outdated milling equipment in use could not meet the technical requirements for product quality.

A renowned flame retardant company in Yixing, specializing in ultra-fine magnesium hydroxide, initially used a domestic jet mill but faced challenges with low production capacity and high energy consumption while producing a particle size of D50=2-4μm.

A company in Iran, focused on producing ultra-fine zircon sand and zirconium silicate powder, evaluated different suppliers in China and abroad. After conducting a thorough 1:1 industrial trial at Zhengyuan, they opted for the LHM ultra-fine ball mill classification line.

As the global demand for ultra-fine food powders continues to grow, South Korean manufacturers are seeking ways to enhance product quality while minimizing energy costs. One major food company conducted trials across multiple countries to find the right solution.

The metal powder industry in Hunan is expanding rapidly, driven by increasing demand for high-performance materials. A prominent local metal powder company recently purchased five air classification units from us to enhance their production capacity.

This silicon carbide factory in Shandong primarily produces F230-F800 grade products. They initially struggled with outdated classification equipment, which had low precision and high energy consumption.

A steel manufacturer in Shandong uses blast furnace slag from their ironmaking process to produce building materials like cement and concrete. Back in 2007, they visited Zhengyuan to explore ultra-fine grinding solutions and decided to purchase an LHM ultra-fine ball mill classification line.