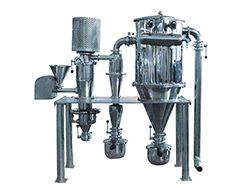

Why Choose Our Lab Jet Mill?

LHL lab jet mill is a small laboratory grinding equipment designed for grinding a small quantity of materials. - This jet mill can complete material grinding and classification at a stroke, and the desired particle size is adjustable. So, it is easy to use and can suit customers’ varied demands.

- The grinding equipment also comes with powder-disaggregating and particle-shaping functions.

- Easy-open structure makes the lab jet mill easy for maintenance and cleaning. The grinder conforms to GMP requirements.

- PLC controlled or electromechanical controlled, the jet mill is easy for operation and offers reliable performance.

How Does Lab Jet Mill Work?

Firstly, after cooling, filtering and drying, the compressed air will be injected into the milling chamber in supersonic speed via nozzles. In the milling chamber of the lab jet mill, the accelerated materials will converge at the meeting point where several jet streams met with each other. Thus, the materials will collide with each other and finally result in ultra-fine particles.

Next, due to upward airflow in the milling chamber, the pulverized materials are transferred to the impeller classification-section, in which the relatively coarse particles and fine particles are separated with each other with the help of centrifugal force of impellers and the draught force of blowers.

Then, the relatively coarse particles will naturally return to the milling chamber for gravity, and the qualified fine particles are connected by cyclone collectors built in our lab jet mill. Meanwhile, superfine particles will be connected by bag collectors and filtered air will be discharged via draft fans.

Contact Us Now

Need Help ?

Please fill out the form and tell us in more detail about your query and we will get back to you as soon as possible.

- E-mail: wfzy1998@gmail.com

- WhatsApp: +86-13465660184

Other Products

-

- LHS Fusion Machine Along with the development of technology, new materials have been widely used. These materials feature the structure that micron-sized materials are covered with nano scale materials.

-

- Superfine Ball Mill Production Line This large-scale production line combines an ultrafine ball mill with a self-diffusing classifier to ensure continuous, efficient powder production.

-

- Wet Ultrafine Grinding Machine For producing the same amount of material, this wet ultrafine grinding machine consumes 30% less energy in comparison with conventional grinding equipment.

-

- High speed Mixer Our LHH drum blender is the newest industrial mixer developed by our company, absorbing advanced foreign technology. Based on effective mixing performance ...