Applications

According to its superior mixing performance, our LHS conical mixer have found a wide range of applications in mixing various materials such as lithium battery material, electronic component, electrical apparatus element, ceramic component, powdered carbon, pharmaceutical, cosmetic, pigment, magnet, fuel cell, biological material, thermal material, powder metal, cement material, etc.

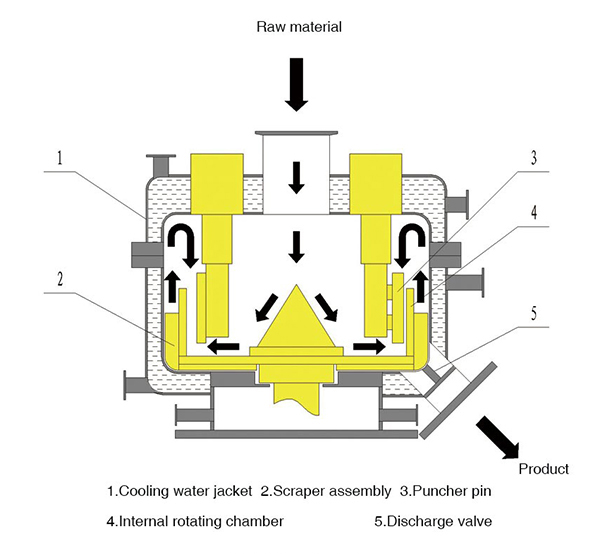

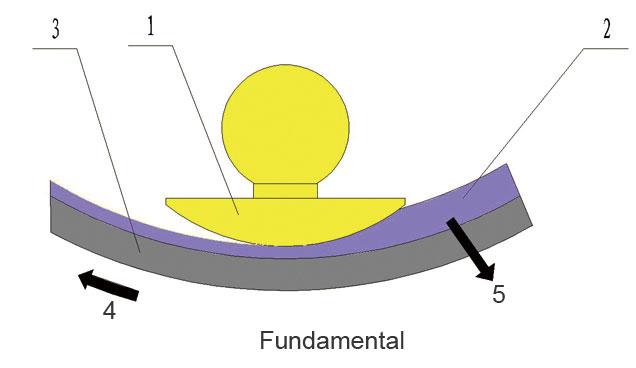

Working Principle

The materials inside the conical mixer are continually subject to extrusion force, shear force and friction force in the high speed rotating mixing chamber. Under the function of friction force, the surface of particles reaches a molten condition. Thus, a micron-sized particle can be coated by many nano scale particles.