Technical Parameters

| Data \ Model | Fineness (um) | Power(kw) | Handling capacity(t/h) |

| LHU-10 | 2-150 | 1.5-2.2 | 0.05-3 |

| LHU-20 | 2-150 | 3-4 | 0.15-0.75 |

| LHU-40 | 2-150 | 5.5-7.5 | 0.3-1.5 |

| LHU-80 | 2-150 | 11-15 | 0.6-3 |

| LHU-160 | 2-150 | 18.5-22 | 1.5-6 |

| LHU-320 | 2-150 | 30-37 | 3-12 |

| LHU-630 | 2-150 | 37-45 | 6-25 |

| LHU-1250 | 2-150 | 75-90 | 10-50 |

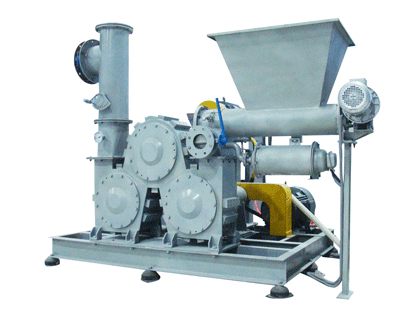

Working Principle

LHU contraflow classifier delivers the materials from wind suction device to classifier. And then, under the centrifugal force from classifier wheel and the gravity produced by airflow orientation device, the particles will finally have fine and coarse classifying.

Performance Advantages and Applications

- LHU contraflow classifier has the advantage of high classifying efficiency, which is 30% more higher than that of other classifiers, and can most quickly separate the ultrafine particles from the materials within the d97= 5-250 microns.

- LHU contraflow classifier featured with strong dispersibility is perfect for viscous material, materials of worse fluidity and so on.

- The classifying range is adjustable within D97=5―100 microns.

- LHU contraflow classifier can use the machine whose processing capacity is within 0.05―50t/h.

- It forms online operation with other classifiers.

- LHU contraflow classifier also can constitute line operation with ball mill, impact mill and various other grinding equipments.

Process Flow

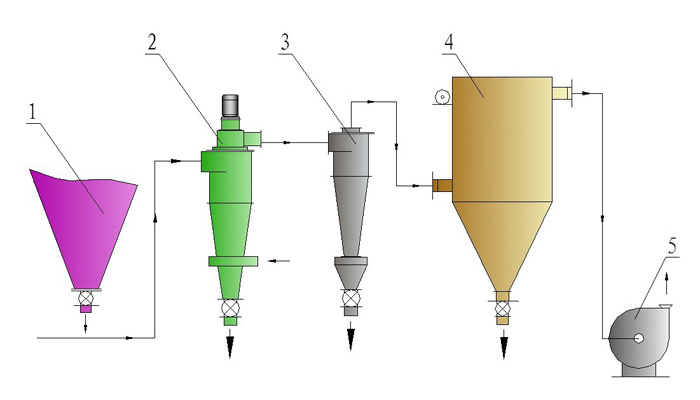

Flow Chart Ⅰ (stand-alone operation mode)

1. Feeding system

2. Contraflow classifier

3. Cyclonic collector

4. Pulsed dust collector

5. Induced draft fan

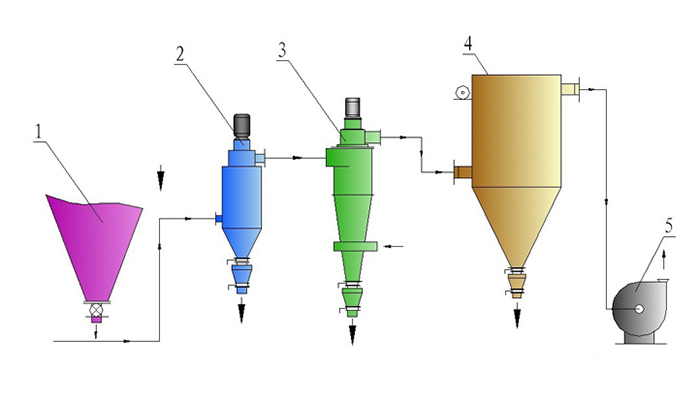

Flow Chart Ⅱ (joint operation mode with distributing classifier)

1. Feeding system

2. Distributing classifier

3. Contraflow classifier

4. Cyclonic collector

5. Pulsed dust collector

6. Induced draft fan