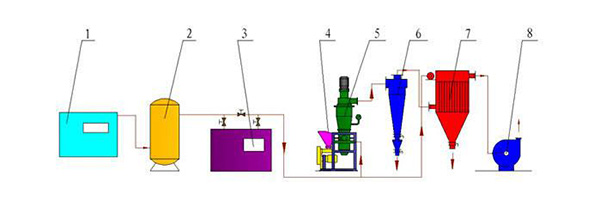

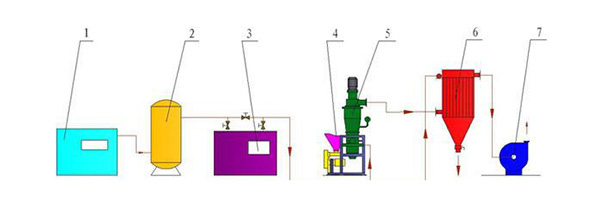

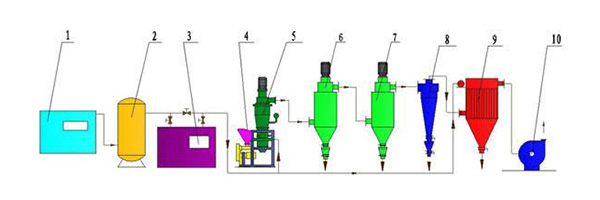

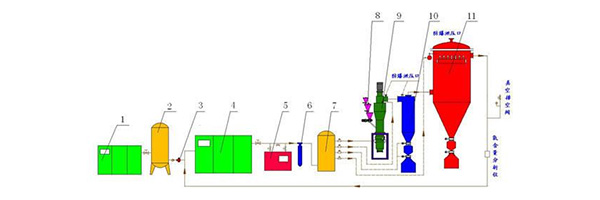

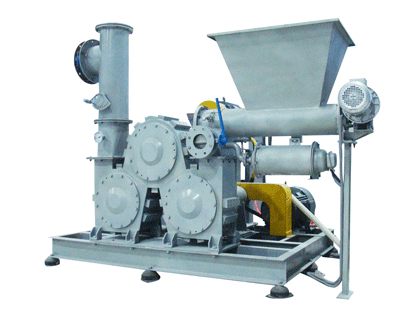

Fluidized Bed Jet Mill

The fluidized bed jet mill combines fluidized bed jet milling technology with self-diffusing classification, offering a modern approach to ultrafine powder processing. Compared to traditional fluidized bed jet mills, it stands out for its lower energy consumption, finer product output, and enhanced reliability. These advantages make it a popular choice for processing a wide range of powder materials in industries requiring ultrafine precision.