Technical Parameters

| Model/Parameters | LHX-250 | LHX-500 | LHX-750 | LHX-1000 | LHX-1250 |

| Productivity | 0.5 | 1 | 1.5 | 2 | 2.5 |

| Rotor diameter (mm) | 250 | 500 | 750 | 1000 | 1250 |

| Revolving speed (r/min) | 9550 | 4775 | 3183 | 2387 | 1910 |

| Fineness (μm) | 2~250 |

| Power (KW) | 11 ~ 18.5 | 30 ~ 45 | 45 ~ 75 | 55 ~ 110 | 75 ~ 132 |

| Air Capacity (m3/min) | 20 | 35 | 55 | 75 | 85 |

| Milling Capacity (kg/h) | 30 ~ 800 | 80 ~ 2000 | 100~ 3000 | 200 ~ 4500 | 300~6000 |

| Weight (kg) | 500 | 1100 | 2300 | 3000 | 360 |

| Dimensions (mm) | 1280 × 600 × 720 | 1690 × 880 × 930 | 2210 × 1100 × 15 | 2510 × 1330 × 16 | 2800 × 1580 × 17 |

Features

- Product fineness and production capacity can be controlled by vertically adjusting gap size between rotor and stator without dismantling the air swept mill. The adjustment range of gap size is 0-5mm.

- Some wearing parts such as the rotor are made of composite wear-resistant materials. Thus they feature minimum wear, non-pollution to materials and long service life.

- The LHX air swept mill boasts a wide range of milling capacity. The fineness can be adjustable from 2μm to 250μm. In addition, it also can use classifier to obtain products within the same fineness range.

- This size reduction machine owns extremely high reduction efficiency. To be specific, under the highest line speed of rotor outer end that reaches 125m/s, the materials can be smashed instantly without over crushing.

- Scientifically designed and reasonably arranged interior structure of the mill chamber can ensure that the materials can be dispersed when being ground, which basically avoid dust being stuck to the wall. Especially, the air swept mill is the best choice for milling sticky and aggregated materials.

- During the milling process, large air flow generated by rotation of the rotor can cool the materials. Thereby, this impact grinding machine is particularly applicable to smash thermoplastic materials, low melting point materials and fiber materials.

- Due to the PLC intelligent control system, simple operation and easy maintenance can be achieved. In addition, the impact mill is easy to clean and can be conveniently switched to grinding another type of material, which reduces labor intensity.

- Our air swept mill comes with efficient shock absorption and noise elimination technology that will extremely reduce noise pollution. It also features negative pressure production which avoids dust pollution.

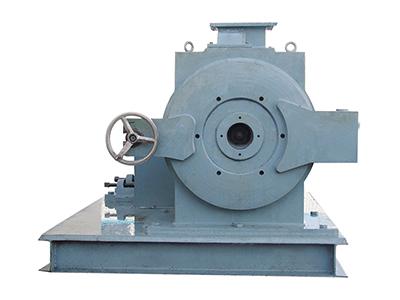

Working Principle

The LHX air swept mill uses variable frequency feeder to deliver materials through the top of the mill into grinding chamber that is equipped with rotor blade. Under the force of super speed cyclone generated by rotation of the rotor blade, the materials enter into the gap between rotor and stator. Then the particles will be cracked and refined due to the force of impact, shear and friction, thus achieving fine powder processing. Going through such processing, the ground material can be not only delivered by negative pressure transporter into connector but also separated by the classifier for continuous crush to the coarse grain.

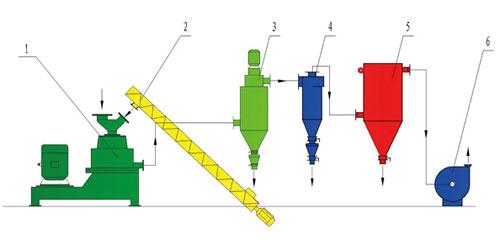

Process Flow

1. Air swept mill

2. Inclined helix

3. Classifier

4. Cyclonic collector

5. Bag collector

6. Induced draft fan

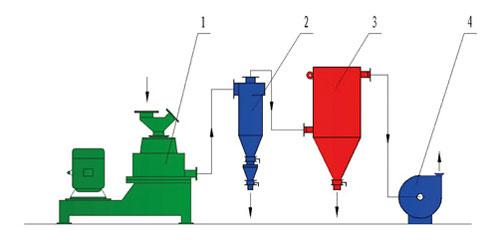

1. Air swept mill

2. Cyclonic collector

3. Bag collector

4. Induced draft fan