Technical Parameters

| Model | Motor power (kW) | Capacity (t/h) | Coating efficiency (%) |

| LHF-500 | 33 | 0.3~1.2 | ≥98 |

| LHF-1000 | 52 | 0.6~3 | ≥98 |

| LHF-2000 | 104 | 1.2~6 | ≥98 |

| LHF-3000 | 155 | 2~9 | ≥98 |

| LHF-5000 | 255 | 4~16 | ≥98 |

Applications

Material enters the powder coating machine (surface modification) through the feeding system, while the modification agent is added using a metering pump. Inside the powder coating machine, both the material and agent undergo high-speed mixing multiple times. The heat generated by the rapid motion of the equipment and the material enables the modification agent to coat the powder’s surface. The final product is then collected through a negative pressure collection system.

Features

- Supports continuous production with a large throughput. It can operate independently or be integrated with various ultrafine grinding machines

- Achieves a high coating rate and activation index, with minimal consumption of coating agents

- Prevents particle agglomeration, eliminating the need for additional screening and allowing direct packaging of the modified product

- Modification temperature can be adjusted based on the specific material properties

- Operates under negative pressure, preventing dust emission and ensuring a clean working environment

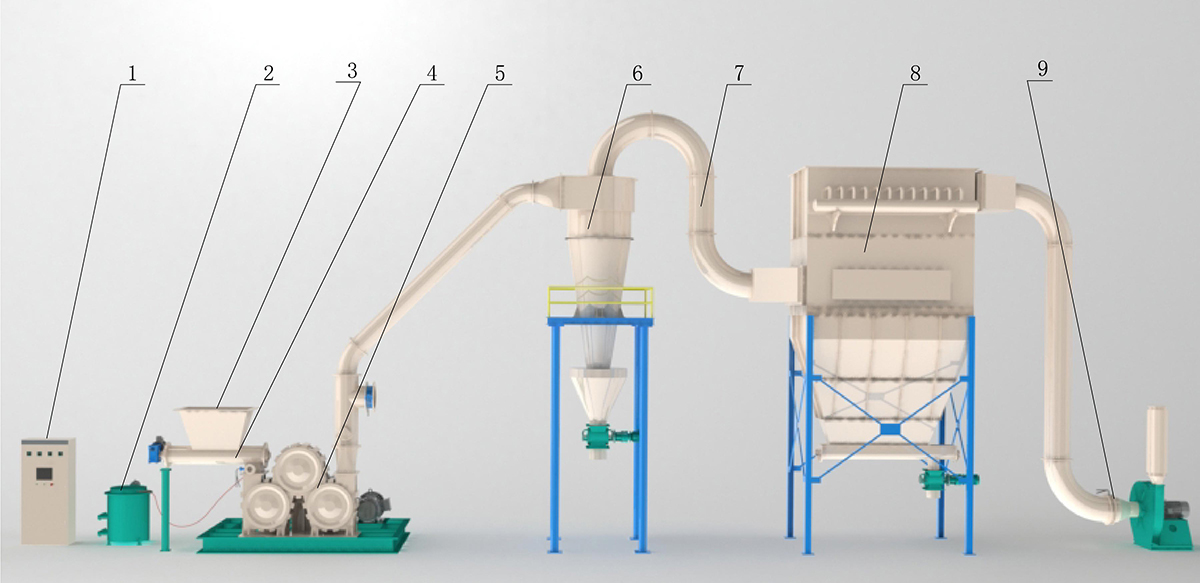

Process Flow

1. Electric control cabinet

2. Reagent tank

3. Hopper

4. Material feeder

5. Powder coating machine

6. Cyclone separator

7. Piping

8. Bag filter

9. Draft fan

Working Principle

The feeding system introduces the material into the powder coating machine, with the modification agent being metered in simultaneously. Inside the chamber, repeated high-speed mixing occurs, utilizing the heat from the rapid movement of both the equipment and material to ensure the modification agent thoroughly coats the powder’s surface. The finished product is collected via a negative pressure system.