Technical Parameters

| Model \ Data | LHI-20 | LHI-50 | LHI-70 | LHI-150 | LHI-260 |

| Feed size(mm) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Fineness(um) | 10~150 | 10~150 | 10~150 | 10~150 | 10~150 |

| Main power(kw) | 7.5-11 | 15-22 | 30-45 | 75-90 | 132-160 |

| Capacity (t/h) | 0.15~1 | 0.35~2 | 0.75~4 | 1.5~7.5 | 3~15 |

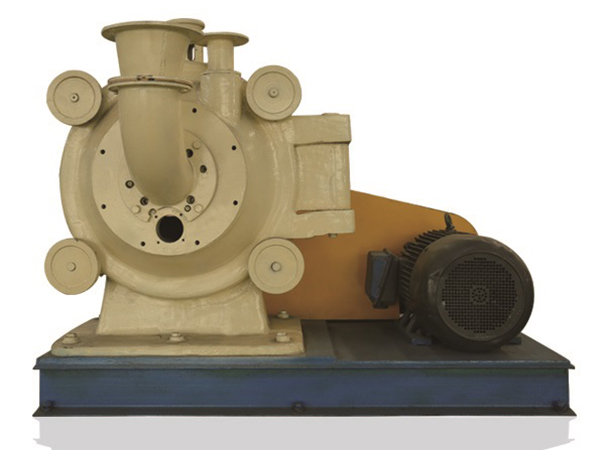

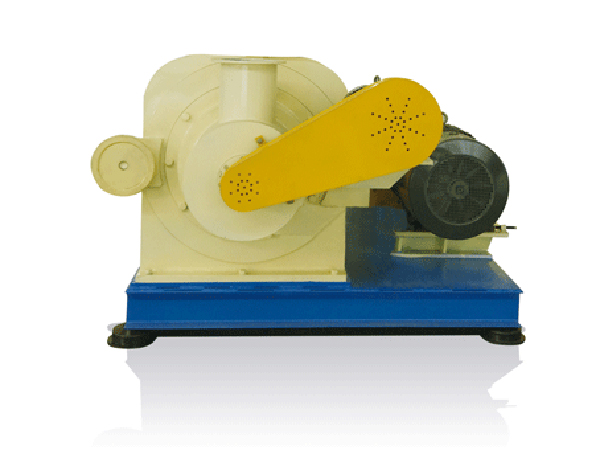

Performance Advantages

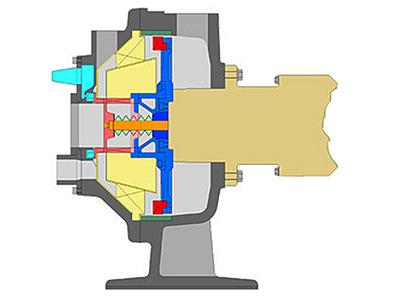

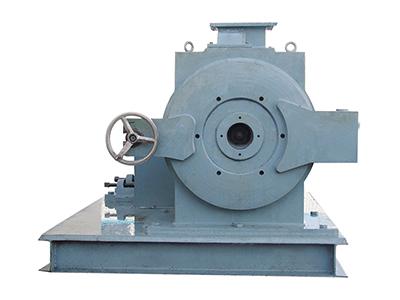

- Both the grinding rotor and classifying wheel are driven by the same motor, which has the advantages of compact structure, high energy-conversion efficiency and low energy consumption.

- The grinding rotor, rotating speed of classifying wheel and the wind volume can be adjustable. The LHI horizontal impact mill can produce the med-fineness finished products within D97=25~150μm and is also more suitable for producing the finished products whose particles are narrowly distributed.

- The crushing parts featured with long service life use the new composite wear-resistant materials. Processing the materials whose Mons' hardness scale is less than 5 is pollution-free.

- LHI horizontal impact mill is featured with quick-opening structure. And the complete machine is easy for dismounting and cleaning, and suitable for refueling operation.

- LHI horizontal impact mill has the advantages of compact design, less space demand and cost-effective.

- It is featured with overall pressure-resisting design. LHI horizontal impact mill uses the inert gas closed-circuit circulation device for smashing the inflammable and explosive materials.

Applications

LHI horizontal impact mill is particularly suitable for crushing and processing epoxy resins, polyurethane, polyester fiber, limestone, dye, gelatine, wheat, and various other materials. It is widely used in crushing materials for chemical industry, building materials, food, medicine, environmental protection industries and so on.

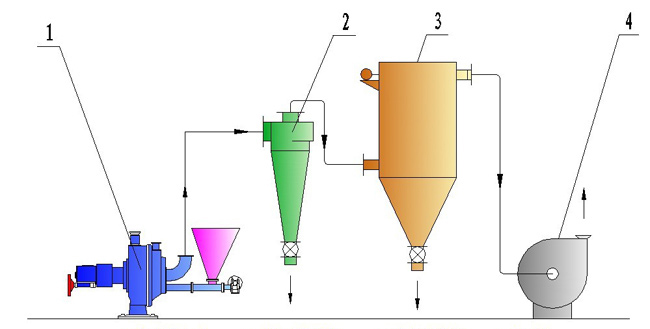

Process Flow

1. Horizontal impact mill

2. Cyclonic collector

3. Pulsed dust collector

4. Induced draft fan