-

-

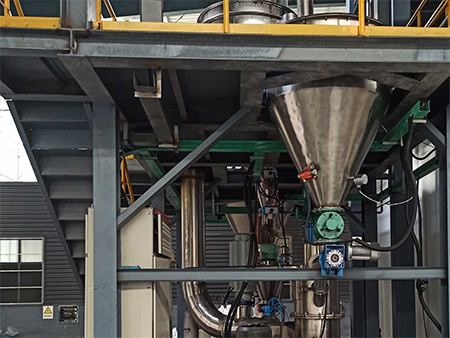

Powder EquipmentJet Mill

Find Out More

Find Out More

-

-

Powder EquipmentImpact Mill

Find Out More

Find Out More

-

-

Powder EquipmentAir Classifier

Find Out More

Find Out More

-

-

Powder EquipmentPowder Surface Modification

Find Out More

Find Out More

Our powder processing equipment is tailored to enhance the production of both cathode and anode materials used in batteries, ensuring high efficiency and exceptional material quality.

- lithium cobalt oxide (LCO) and lithium manganese oxide (LMO)

- Nickel variants (NCM & NCA)

- Specialized lithium cobalt formulations

- Phosphate-based lithium compounds (LFP & LMFP)

- Spherical and artificial graphite

- Coke powder and carbon microspheres

- Pitch coke and silicon carbon materials

- Biomass carbon

ShanShan, a company in Inner Mongolia, after carefully evaluating various options, chose our shaping machines for their battery materials production. With over 20 machines running smoothly for more than three years, these shaping machines have been running efficiently for over three years, ensuring consistent and precise control of particle sizes. With tight regulation of Dmin and Dmax values, they deliver high product yields with minimal maintenance. The reliability and performance of the LHZ shaping machines have proven essential for large-scale battery material production, offering both stability and efficiency.

Shijiazhuang Shangtai Company faced ongoing challenges with their previous roller mill system, including inconsistent particle size, excessive D100 values, high wear, and low production output. After months of failed modifications, they decided to upgrade in 2018 and chose our LHG-300 and LHG-450 roller mills. Since making that decision, the company has experienced a remarkable transformation: production capacity has more than tripled, large batch processing has become consistently stable, and maintenance intervals have increased from 15 days to over 4 months. Now operating more than 20 units, the company has significantly boosted both product quality and operational efficiency, strengthening its competitive edge in the industry.

Our team will work with you to find the right solution for your production needs.

Non-Metallic Mineral Processing

We specialize in manufacturing efficient equipment for the processing of various non-metallic minerals, tailored to both hard and soft material categories.

Fine Chemical Manufacturing

We offer powder processing equipment designed to meet the precise demands of the fine chemical industry. Whether you're handling everyday compounds or specialized materials, our technology ensures efficient ...

Ceramic Material Manufacturing

Zhengyuan offers advanced equipment solutions for processing a wide range of materials used in the ceramic and construction industries.