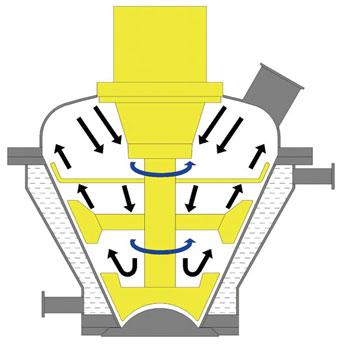

High speed Mixer

Our LHH drum blender is the newest industrial mixer developed by our company, absorbing advanced foreign technology. Based on effective mixing performance, it has found a wide range of application in blending slurry, liquid and powder. In such blending process, it features different functions such as intensive mixing, balling, dispersing, crushing, drying, prilling, cladding, etc. In addition, the mixing machine can also be used in mixing anode and cathode materials of lithium battery.