Parameters

| Data \ Model | Feed size(mm) | Moisture(%) | Fineness(um) | Capacity(t/h) | Main power(kw) |

| LHG-150 | < 10 | < 10 | 2~75 | 0.5~6.5 | 75 |

| LHG-300 | < 10 | < 10 | 2~75 | 1~13 | 110 |

| LHG-450 | < 10 | < 10 | 2~75 | 1.6~19 | 160 |

| LHG-750 | < 10 | < 10 | 2~75 | 3~30 | 250 |

| LHG-900 | < 10 | < 10 | 2~75 | 5~50 | 355 |

Applications

Our roller mills are primarily used for superfine grinding of various dry powder materials. This kind of grinding mill is extensively used in industries like nonmetal mining, chemical engineering, building material production, metallurgic, new material manufacturing, and food production, etc.

Fibre texture material (Chinese medicine and wood powder, etc.) grinding are also possible.

Working Principle

Roller mill LHG has the similar working principle to superfine impact mill and jet mill:

- Feeding and grinding: After the materials are fed into milling chamber, they will be ground into superfine powders by grinding roller.

- Classification: relatively coarse and fine powders will be separated from each other under the centrifugal force of classification impellers and the draft force of induced draft fans.

- Collection: Qualified products will be collected and unqualified products will re-enter into milling chamber for second time grinding.

Cleaned air will be discharged by induced draft fans.

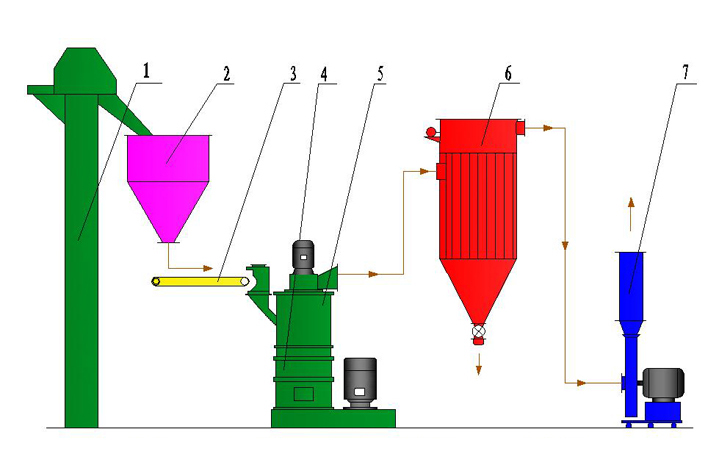

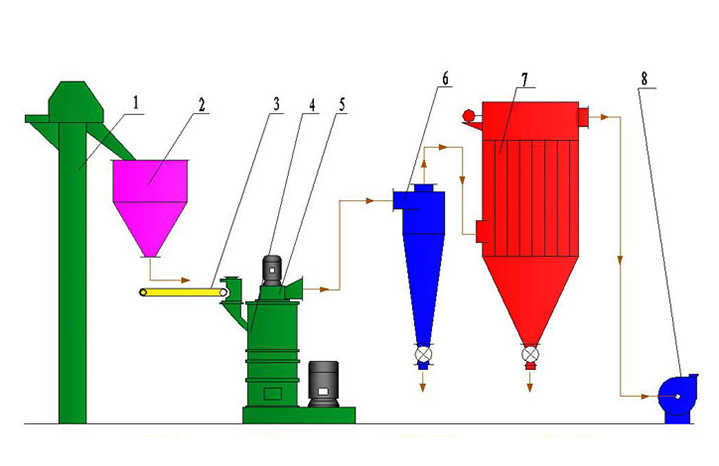

Process Flow

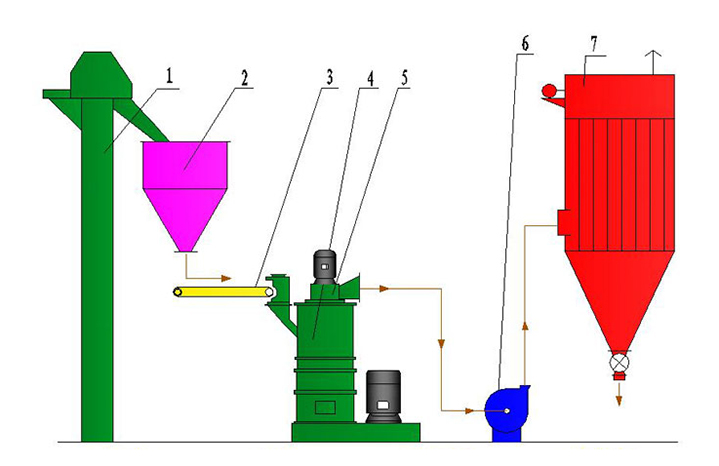

1. Bucket elevator

2. Storage hopper

3. Material feeder

4. Roller mill grinding chamber

5. Roller mill classifier

6. Pulse bag-type collector

7. Induced draft fan

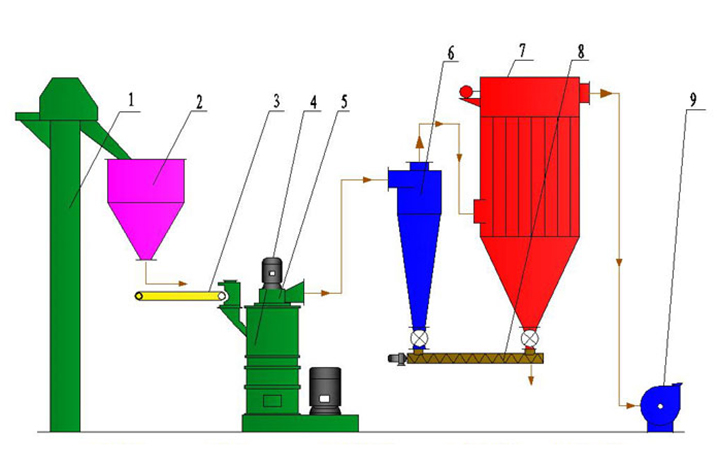

1. Bucket elevator

2. Storage hopper

3. Material feeder

4. Main machine of vertical roller mill

5. Roller mill classifier

6. Cyclone separator

7. Pulsed dust collection

8. Screw conveyor for material feed back

9. Induced daft fan

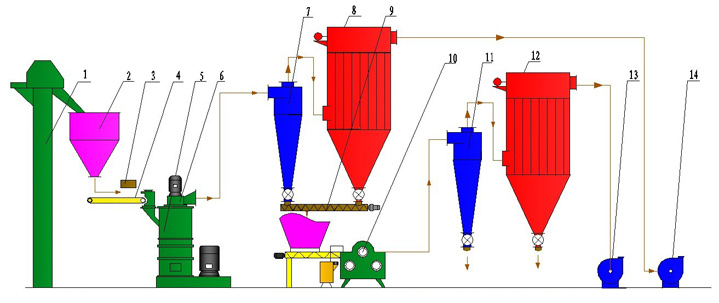

1. Bucket elevator

2. Storage hopper

3. Material feeder

4. Main machine of roller mill

5. Roller mill classifier

6. Induced draft fan

7. Pulse bag-type collector

1. Bucket elevator

2. Storage hopper

3. Material feeder

4. Main machine of grinding mill

5. Roller mill classifier

6. Cyclone separator

7. Dust collector

8. Induced draft fan

1. Bucket elevator

2. Hopper

3. Metal separator

4. Material feeder

5. Roller mill grinding chamber

6. Roller mill classifier

7. Cyclone separator

8. Pulse dust collector

9. Screw conveyor for back feeding

10. Powder coating machine (surface modification)

11. Cyclone separator Ⅱ

12. Pulse dust collector Ⅱ

13. Draft fan Ⅰ

14. Draft fan Ⅱ