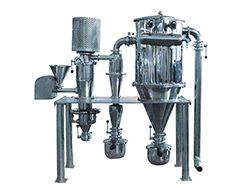

Technical Parameter

| Size | LHC Laboratory Size |

| Particle Size | ≤1mm |

| Ground Particle Size | 3~100um |

| Air Consumption | 1~1.5m³/min |

| Air Pressure | 0.8~1MPa |

| Motor Power | Host | 0.75kw |

| Classifier | 0.75kw |

| Fan | 2.2kw |

| Feeding system | 0.37kw |

| Compressor | 7.5~11kw |

| Capacity (kg/h) | 1~30kg/h |

Working Principle

After being cooled, filtrated and dried, the compressed air is instilled into rotational grinding chamber through nozzles as supersonic flow. In the chamber, the materials get fluidized.

Then the accelerated materials blend at the converging point where many jet streams also joint together. They become ultrafine particles after severe collision, frustration and shearing. The ground materials are transferred to impeller classification area by rising stream.

Under the influence of centrifugal force and fan draught, the ultrafine powder can be separated from the rough. Rough powders return to the grinding chamber to be ground with the help of their own gravity, while the qualified ultrafine powders enter a cyclone collector together with the stream. Qualified ultrafine powders are collected by a bag filter, and filtered gas is discharged by induced draft fans.