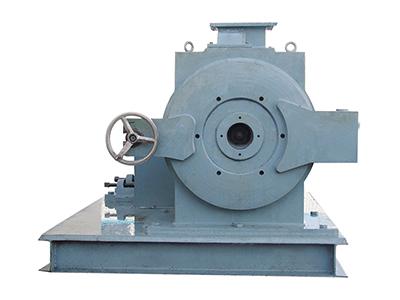

Pin Mill

LHN pin mill delivers the materials from top feeding device to the crushing chamber of main engine. There are two clutch plates mounted with evenly distributed pin bar in the crushing chamber. And also the two clutch plates run at high speed in opposite direction and the highest relative velocity is 250m/s. Then, the materials impact the pin bar at extremely high speed. In addition, the air turbulence effect will also facilitate the high-velocity impact among particles. Finally, LHN pin mill can meet the fineness requirement of finished products by adjusting the rotational speed of clutch plate.