-

- LHB Self-diffluent Classifier Self-diffluent classifier is a latest Zhengyuan self-developed superfine air classifier, could be used to sort powder materials in submicron and nano levels, wipe off impurities and scatter powder materials.

-

- LHP Multi-Stage Classifier LHP multi-stage classifier, which is a closed-loop system composed of several LHB self-diffluent classifiers, can sort materials into different groups with different particle size distribution.

-

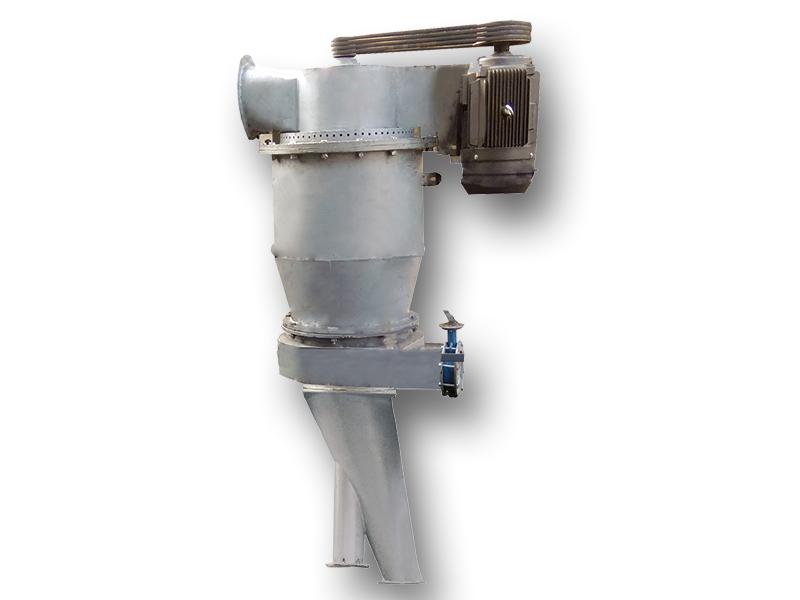

- LHB-C Whirlwind Air Classifier The whirlwind air classifier of LHB-C series for coarse powder is innovatively designed. It is composed of classifier, housing, air dispersing cone, air circulating unit, and fineness control device. The raw material is delivered to the air separator and then raised by airflow.

-

- LHU Contraflow Classifier LHU contraflow classifier delivers the materials from wind suction device to classifier. And then, under the centrifugal force from classifier wheel and the gravity produced by airflow orientation device, the particles will finally have fine and coarse classifying.

-

- LHB Centrifugal Air Classifier LHB Centrifugal Air Classifier is independently developed and produced by our company. It combines self-distribution grading technology and centrifugal grading technology to make full use of the high-temperature airflow in the production line (temperature up to 100-300 °C) to achieve ultra-fine grading effect. Its main features are: The high-temperature airflow can be fully utilized to ensure the full dispersion of materials ...

- Low energy consumption: Our air classifiers can save as much as 50% energy comparing to traditional vertical type or horizontal type classifiers.

- High production efficiency: our air classifier combined the advantages of inertial classification technology and centrifugal classification technology.

- High precision classification help guarantee that there is no oversize granularity and remains, etc. in finished products.

- Longer service life: our air classifier has a low rotation speed while classifying materials in the same size, which help reduce the wear of impellers.

- Full range of specifications: different air classifiers will be offered for your different needs.

- Can be matched-use with wide variety of grinding mills, like ball mills, Raymond mills, impact mills or jet mills, etc.

- Eco-friendly: No dust pollution for negative pressure production environment.

- High automation gives a simple operation and stable performance.

Materials are fed into self-diffluent classification system for first time separating: majority coarse materials will be separated and the remained coarse materials will be sorted out in second time classifying. Qualified powders will be collected together and coarse materials will be discharged from dump valves.

Our team will work with you to find the right solution for your production needs.

- E-mail: wfzy1998@gmail.com

- WhatsApp: +86-13465660184

ShanShan, a company in Inner Mongolia, after carefully evaluating various options, chose our shaping machines for their battery materials production. With over 20 machines running smoothly for more than three years ...

In Uzbekistan, a local company sought to capitalize on its abundant calcite resources to develop a high-grade calcium carbonate project. However, the outdated milling equipment in use could not meet the technical requirements for product quality.

A renowned flame retardant company in Yixing, specializing in ultra-fine magnesium hydroxide, initially used a domestic jet mill but faced challenges with low production capacity and high energy consumption while producing a particle size of D50=2-4μm.

A company in Iran, focused on producing ultra-fine zircon sand and zirconium silicate powder, evaluated different suppliers in China and abroad. After conducting a thorough 1:1 industrial trial at Zhengyuan, they opted for the LHM ultra-fine ball mill classification line.

As the global demand for ultra-fine food powders continues to grow, South Korean manufacturers are seeking ways to enhance product quality while minimizing energy costs. One major food company conducted trials across multiple countries to find the right solution.

The metal powder industry in Hunan is expanding rapidly, driven by increasing demand for high-performance materials. A prominent local metal powder company recently purchased five air classification units from us to enhance their production capacity.

This silicon carbide factory in Shandong primarily produces F230-F800 grade products. They initially struggled with outdated classification equipment, which had low precision and high energy consumption.

A steel manufacturer in Shandong uses blast furnace slag from their ironmaking process to produce building materials like cement and concrete. Back in 2007, they visited Zhengyuan to explore ultra-fine grinding solutions and decided to purchase an LHM ultra-fine ball mill classification line.