Parameters

| Spec \ Data | LHP-1 | LHP-2 | LHP-3 | LHP-4 | LHP-5 | LHP-6 |

| 2 | 3 | 2 | 3 | 2 | 3 | 2 | 3 | 2 | 3 | 2 | 3 |

| Handling capacity (t/h) | 50- 200 | 30- 150 | 300- 800 | 200- 700 | 600- 1200 | 500- 1000 | 1000- 2500 | 800- 2000 | 1500- 3500 | 1200- 3000 | 2500- 5000 | 2000- 4000 |

| Fineness (um) | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 | 2-150 |

| Efficiency (η=%) | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 | 75-95 |

| Main power (kw) | 3.7 | 5.2 | 8 | 13.5 | 11 | 16.5 | 13 | 20.5 | 18.5 | 33.5 | 29.5 | 51.5 |

Features

- Capable of generating multiple particle size grades simultaneously, this classifier can replace several single-stage classifiers, optimizing space and efficiency in production processes

- It reduces energy consumption by up to 50% and enhances classification efficiency by 50% compared to traditional classifiers, offering significant environmental and economic benefits

- Ensures high precision in particle sizing, effectively minimizing oversized particles and residual materials to guarantee consistency and quality in the final product

- The classifier can be tailored with unique structural designs to meet diverse industrial requirements, providing flexibility across various applications

- Designed to operate under negative pressure, the classifier prevents any dust emissions, contributing to a cleaner and safer working environment

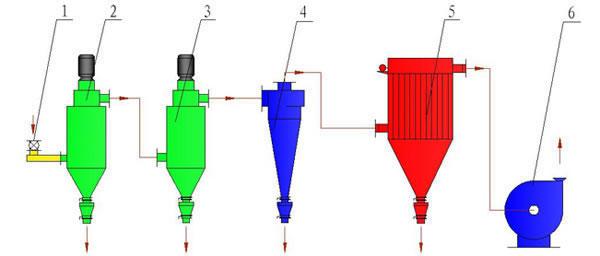

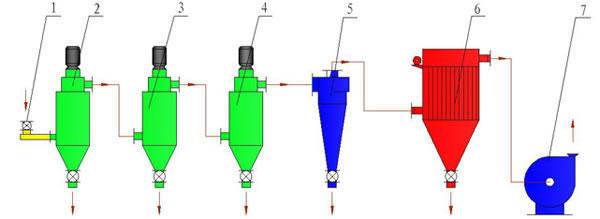

Process Flow

1. Material feeding system

2. Classifier I

3. Classifier II

4. Cyclonic collector

5. Pulsed dust collector

6. Induced draft fan

1. Material feeding system

2. Classifier I

3. Classifier II

4. Classifier III

5. Cyclonic collector

6. Pulsed dust collector

7. Induced draft fan

Working Principle

The multi-stage classifier system uses a series of integrated classifiers to create a highly efficient closed-loop for precise particle size separation. As material enters the system, an initial classification occurs where the majority of coarse particles are filtered out. The remaining fine particles, along with some residual coarse material, are then carried by an upward airflow into the second classification zone. Here, a turbine performs a more refined separation, allowing only the finest particles to pass through the classifier wheel for collection. Coarse particles are discharged through a separate valve.