Shaping Machine

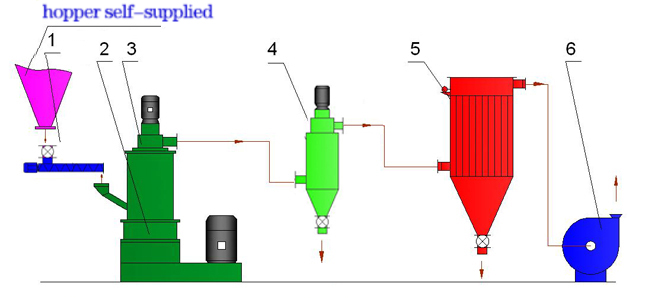

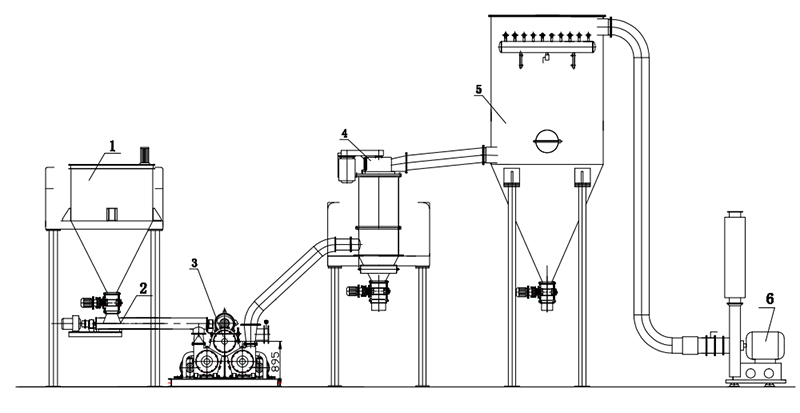

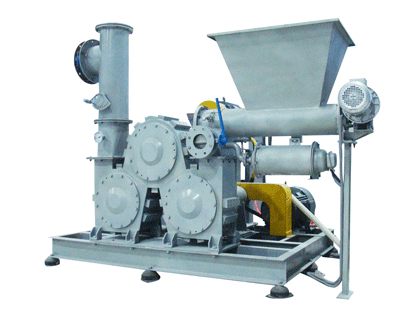

Powder processing equipment for the production of battery anode materials

- Capable of shaping high-end materials like Dmin≥2μm in a single process, unlike other systems that require multiple passes, leading to improved efficiency and higher product yield

- Ensures that final particles have excellent roundness and high tap density, meeting strict quality standards

- Designed for durability, with minimal wear and low part replacement needs, making it ideal for long-term production

- Applies even force during the shaping process, preventing over-grinding and ensuring consistent particle quality

- Provides precise classification, with tight control over particle size distribution, leading to efficient separation, high yield, and reduced waste

The newly developed graphite spheroidization shaping machine was developed and manufactured by Zhengyuan to meet the rapid growth demands of the battery materials industry. This shaping equipment is characterized by high shaping efficiency, low energy consumption, and a large single-machine output. Additionally, its enhanced process design improves operational simplicity, making it a reliable choice for modern battery material production.