| Model \ Data | |||||||

| Feed size(mm) | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 3 | ≤ 3 |

| Fineness(um) | 2~150 | 2~150 | 2~150 | 2~150 | 2~150 | 2~150 | 2~150 |

| Capacity(kg/h) | 20~150 | 60~300 | 120~700 | 250~1500 | 600~3000 | 1000~4500 | 2000~10000 |

| Air consumption(m3/min) | 3 | 6 | 10 | 20 | 40 | 60 | 120 |

| Air pressure(MPa) | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.8 |

| Installed power (kw) | 30 | 56 | 79.5 | 165 | 310 | 450 | 850 |

- It delivers twice the output compared to standard jet mills, without increasing energy consumption

- The integrated self-diffusing classification system ensures a narrow particle size distribution, and the classifier wheel lasts 5 to 8 times longer than those in conventional designs

- In addition to ultrafine grinding, it also shapes and disperses particles, adding versatility to the production process

- This system can safely process flammable, explosive, or easily oxidized materials using inert gases in a closed-loop, with minimal gas loss

- It operates without a grinding medium at low temperatures, making it perfect for materials with low melting points or those sensitive to heat.

- Its compact design, polished surfaces, and lack of material retention points ensure easy cleaning and maintenance, fully meeting GMP standards

Contact Us Now

Please fill out the form and tell us in more detail about your query and we will get back to you as soon as possible.

- E-mail: wfzy1998@gmail.com

- WhatsApp: +86-13465660184

-

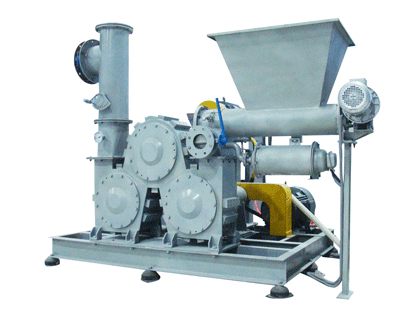

- LHJ Superfine Impact Mill

Our independently developed superfine impact mill offers exceptional versatility, seamlessly integrating ultrafine powder grinding, disaggregation, reshaping, and material modification into a single, efficient system.

-

- LHW Vortex Mill

Our vortex mills can be used for normal temperature pulverizing of thermosensitive materials, like rice, cassava fiber, tobacco stems, soy protein, silica gel, magnesium metal, etc.

-

- Powder Surface Modification Coating Machine

Powder surface modification coating machines generatw heat through high-speed interaction between the rotor and materials, effectively modifying the surface of powder particles.

-

- LHB Lab Air Classifier

Materials are fed into self-diffluent classification system for first time separating. Thus, majority coarse materials will be separated and the remained coarse materials will be sorted out in second tine classifying.