Features

- Compared to conventional jet mills, the impact force on particles of this equipment is increased by 4 times, but the energy consumption is only 1/5-1/8 of conventional equipment.

- The classifier works in a high-temperature steam environment, the particle size cutting point of the classifying wheel is smaller than that in the air environment, and can produce directly the products of D50<1um.

- The steam flow in the ultra-high temperature state is dry, which not only will not increase the moisture content of the material, but also has a material drying function.

- Especially suitable for ultra-fine pulverization of high-viscosity materials. The finished products have poor electrostatic agglomeration and good dispersibility.

- It can make full use of the unused or discharged low-grade superheated steam in electric heating plants and steel mills to achieve low-cost and large-scale ultra-fine powder processing.

- High capacity, it can be used with large industrial boilers

Application

Applicable materials: steel slag, water slag, fly ash, solid sulfur residue, kaolin, titanium dioxide, carbon black and other low-cost processing materials.

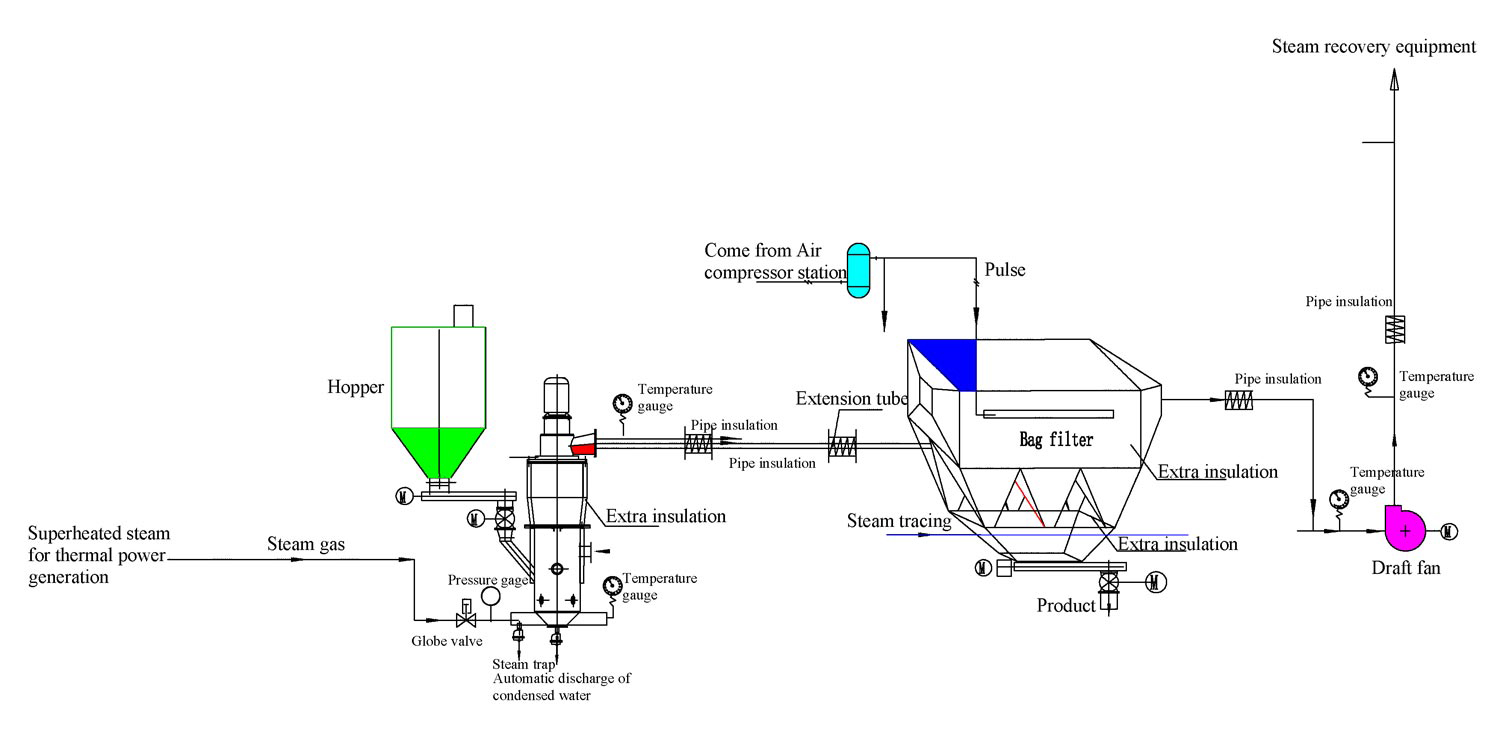

Process Flow

Contact Us Now

Need Help ?

Please fill out the form and tell us in more detail about your query and we will get back to you as soon as possible.

- E-mail: wfzy1998@gmail.com

- WhatsApp: +86-13465660184

Other Products

-

- LHQ Classifying Micronizer Firstly, the LHQ classifying micronizer delivers the materials from feeding device to the crushing chamber. The material is smashed through severe friction, shearing and extrusion of high-speed rotor.

-

- SH Industrial Shredder

Equipped with powerful two-speed swing type hydraulic pusher, which avoids the occurrence of jamming and reduces the wear of the inner rail.

-

- LHI Horizontal Impact Mill Firstly, the LHI horizontal impact mill feeds the materials from feeding device to the crushing chamber. Then, the materials will be smashed through the impact of high-speed rotating hammer.

-

- LHB Lab Air Classifier

Materials are fed into self-diffluent classification system for first time separating. Thus, majority coarse materials will be separated and the remained coarse materials will be sorted out in second tine classifying.