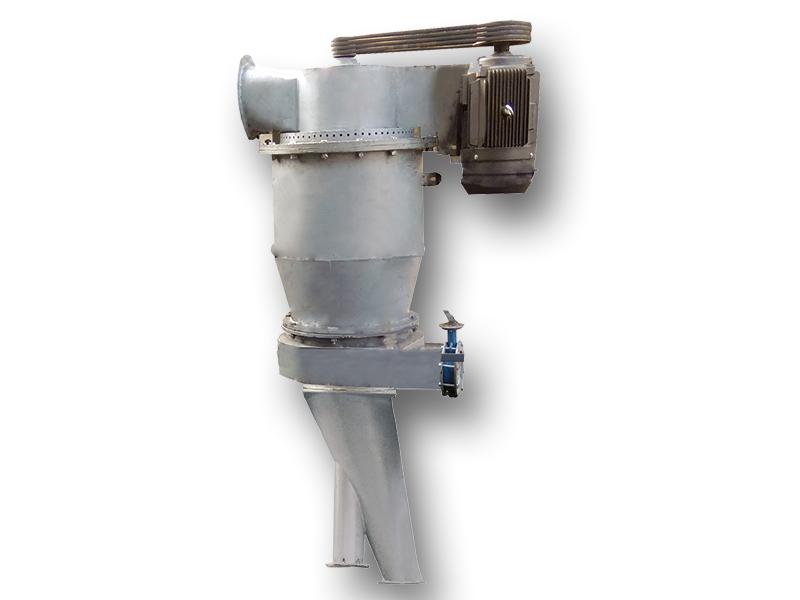

Centrifugal Air Classifier

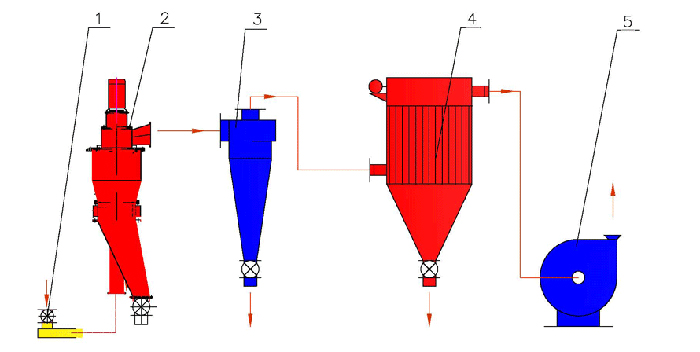

LHB Centrifugal Air Classifier is independently developed and produced by our company. It combines self-distribution grading technology and centrifugal grading technology to make full use of the high-temperature airflow in the production line (temperature up to 100-300 °C) to achieve ultra-fine grading effect. Its main features are: The high-temperature airflow can be fully utilized to ensure the full dispersion of materials, the classification efficiency is high, the cutting point is accurate, the large particles can be strictly controlled, the processing capacity is large, the energy consumption is low, and has high stability.

This equipment is suitable for on-line grading and impurity removal in various high-temperature production lines, and can also be used for the removal of coarse particles in ultrafine powders and nano powders.