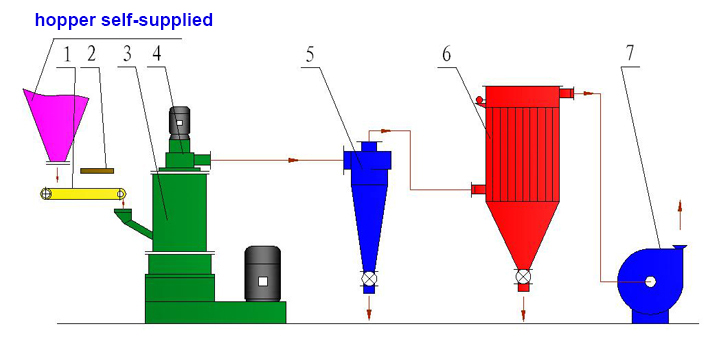

Superfine Impact Mill

Powder processing equipment for the production of battery cathode materials

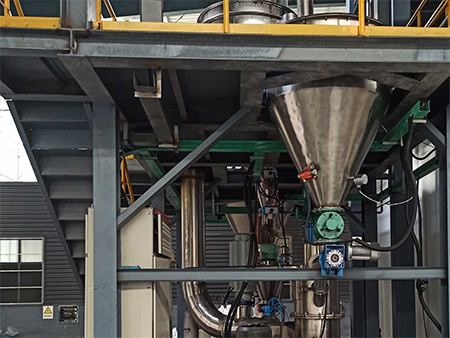

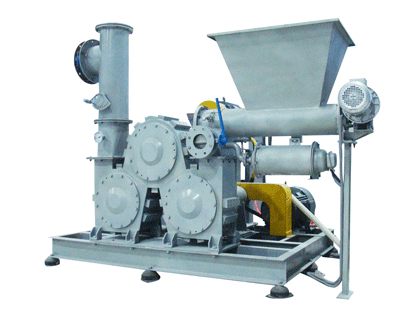

Superfine impact mills are known for their ability to achieve ultrafine particle sizes with exceptional precision, making them an essential tool in the production of advanced materials. This particular mill is optimized for grinding critical battery materials such as lithium titanate, lithium iron phosphate, lithium manganese oxide, and lithium cobalt oxide, ensuring both efficiency and high-quality output.

This superfine impact mill is optimized for processing various battery materials, including lithium titanate, lithium carbonate, lithium hydroxide, and more advanced compounds like lithium iron phosphate and lithium manganese oxide. Its efficiency also extends to materials such as cobalt oxides and ferrous oxalate, ensuring precise and consistent results in high-performance applications.