Parameters

| Model \ Data | LHV-2000 | LHV-4000 | LHV-8000 |

| Main power(kw) | 110 | 220 | 355 |

| Fineness(um) | 2~45 | 2~45 | 2~45 |

| Capacity (t/h) | 1~3 | 2~6 | 4~12 |

Features

- Low energy consumption: because our grinder mill adopted innovative powder disaggregation technology.

- The grinding parts of our powder disaggregate mills are made of wear-resistance composite materials. As a result, our machines have a long service life and low abrasion.

- Granular recovery rate: 100%.

- Air classifiers are equipped for classification of materials with different fineness. In addition, adjusting devices are available for regulating apparent density under prescribed conditions.

- Equalization treatment for rotors and antivibration pads for machine frame, etc. guarantees a stable machine operation and low vibration.

- Wide range for applications: This grinding mill is also suitable for disaggregating of high water-content materials under the help of hot air. Disassembling of inflammable, explosive and easily oxidized materials are also possible (inert gas should be used as medium). If equipped with cooling techniques, the powder grinding mill will be able to disaggregate thermosensitive materials and low-melting-point substances.

- Negative pressure production gives a dust-free manufacturing environment.

- An international-leading intelligent control system is adopted in our grinding equipment. Therefore, our powder disaggregate mills have a reliable and simple operation.

Working Principle

The viscosity, glomerate or caking materials will be transport into braking up chamber by screw feeder. The high-speed rotor disc will impact and shear the glomerate materials to restore them to the original state. The final product will be transported to the collecting area by a stream of upper airflow, and then collected by cyclone and bag filter. Finally purified air will be expelled from draft fan.

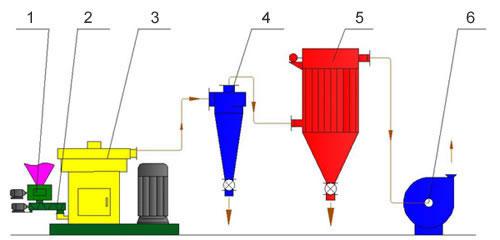

Working Principle

1. Feeding hopper

2. Material feeding system

3. Powder disaggregation system

4. Cyclonic collector

5. Pulsed dust collector

6. Draft fan